If you’re looking to start your own business, chances are you need a sign, which means you need to hire a sign company. Speak to a sign company and they will likely suggest “channel letters.”

But what is a channel letter?

Even if you didn’t know the name, you’ve definitely seen a channel letter. Many shopping centers require their tenants to install channel letter signage as part of the lease, and channel letters have been a long-standing favorite of major retailers for decades. Go to any strip mall or even your local grocery store, and you’ll likely find them everywhere. But just seeing a channel letter sign for yourself won’t tell you what you need to know, which is why we’ve put together a comprehensive list. We hope this information will help you make an informed decision when it’s time to purchase a sign for your business.

HOW TO MAKE A CHANNEL LETTER

Without getting too technical, we’d like to go over how a channel letter is made. First, we cut out the letter backs from a sheet of substrate (usually aluminum or an aluminum composite). Then, we bend a lighter aluminum coil around the shape of the back to form the depth of the letter, also known as a “return.” Together the letter back and the return form what is commonly known as a “can.” If required, lights are installed inside the letter cans. Finally, letter faces are cut and attached to the front of the return; this is usually done with trim cap or (in the case of very large signs) metal molding.

DIFFERENT TYPES OF CHANNEL LETTER

Though the base components of a channel letter (the back, return and face) are universal to this type of sign. There are many ways to approach building a channel letter. Factors like, landlord and code requirements, budget and aesthetic choice will determine which type you go with. Below we’ve listed your likely options:

The most common type of channel letter is front-lit. A solid majority of the signs you see are this type. Front-lit channel letters have an aluminum (or aluminum composite) back, an aluminum return, a 3/16″ acrylic (plexiglass) face and trim cap. Lights (most contemporary signs use LED modules) are installed to the inside of the back of the can so that the acrylic faces of the letters illuminate.

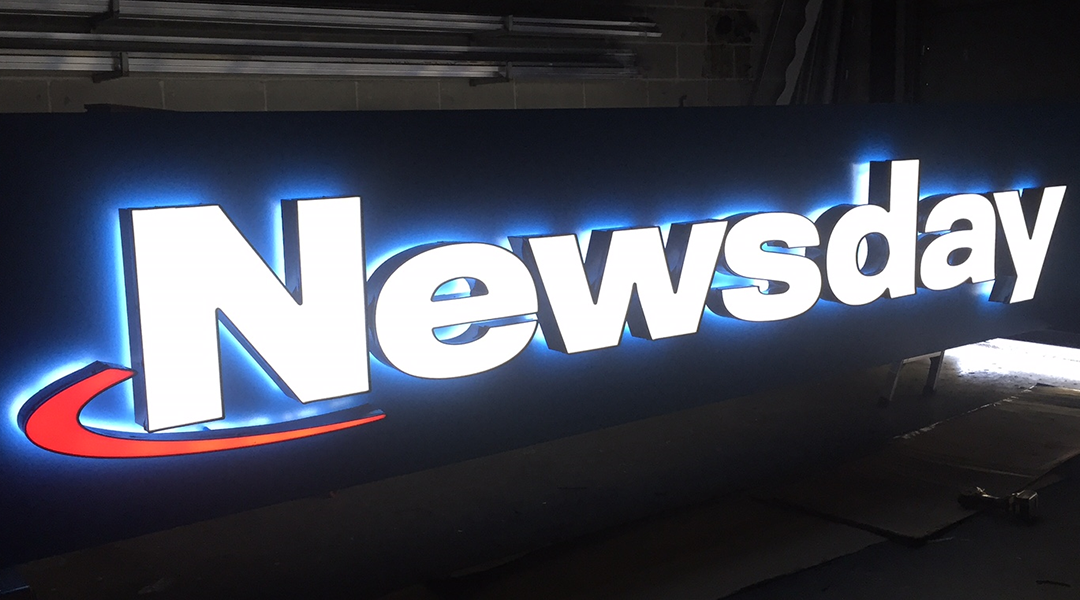

Another common type of channel letter is halo-lit. Instead of aluminum backs and acrylic faces, these channels usually consist of high-quality aluminum faces, welded to aluminum returns. Lighting is installed on clear acrylic letter backs so that it reflects off the inside of the can and illuminates the wall behind the sign.

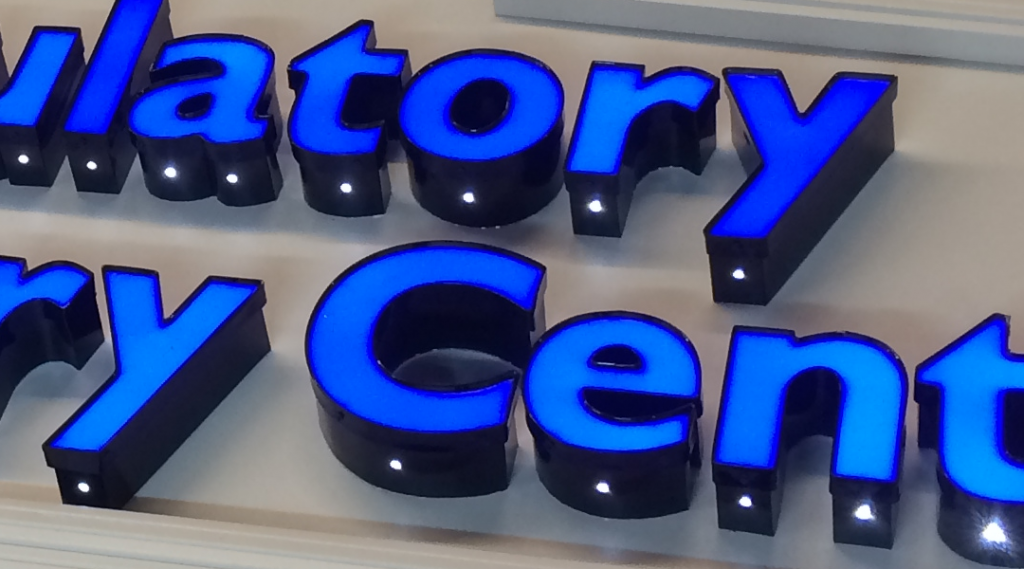

Some channel letters are front and halo-lit. This is achieved by making the faces and the backs out of acrylic, allowing light to pass through both surfaces. This is most effective when vinyl is used to make the light illuminating the wall a different color from the light illuminating the letter face.

Low profile and/or trim less channel letters are alternatives to the standard channel letter, but will result in higher cost due to increased labor and materials. However, the end result often reflects this added investment, especially on interior installations where signs are closer to public view.

Different lighting types can also be used to alter the feel or appearance of a channel letter sign. Open cans (channel letters without faces) with neon tubing or marquee bulbs will make a sign feel more rustic or old-fashioned. A clear acrylic face can deter birds and prevent dust/dirt buildup on exterior elevations.

WHAT A CHANNEL LETTER WILL COST

Whatever sign type you decide to go with, size will likely be the greatest determining factor of cost. Most sign companies price a channel letter on it’s overall height. However, when you compare quotes from different sign companies, it is always important make sure they are offering the same sign. Most sign drawings will include a detail that lists the materials being used. Cross-check these lists and inquire about any differences you see between specifications. The company should be willing to alter their fabrication method to meet the higher standards or be able to demonstrate why the materials they are using will work for your sign. If you have any doubts, they should produce samples of their work to demonstrate their capabilities and expertise.

OTHER CONSIDERATIONS

Those are the basics, but there are a few other things you should know about having a logo made into a channel letter sign:

LETTER STROKE

For a standard channel letter the width or stroke of the letter needs to be wide enough to accommodate the LED modules. If a letter or logo is too small/narrow, either the artwork or fabrication method will need to be adjusted. If adjusting the artwork is not an option, keep in mind that deviating from common channel letter fabrication methods will likely result in higher cost. If your logo has too many fine details, channel letters may not be right for you. A good sign company should be able to tell you this upfront and offer you multiple solutions that will satisfy your signage needs and keep within a budget.

INSTALLATION METHOD

Most channel letters are installed directly to the wall or “flush mounted.” The construction of the building will be a major factor in determining whether this is possible. Because wiring and power supplies are essential components of any lighted sign, your installer will need access behind the wall fascia in order to complete a flush mount installation. If there is no access, your sign may need a raceway or panel behind the letters to house the wiring and power supplies. Raceways are usually painted to match the building fascia so as not to distract the public eye. Panels may be painted to match the fascia or designed to act as part of your sign.

WEEP HOLES

Channel letters installed outside will require weep holes to prevent rainwater from building up inside your sign. This means that the returns in your sign will have small holes in the bottom. This allows light to shine out. If you do not want this, your sign company should be able to include light baffles, which are like little shields or hats for your weep holes. These will prevent light from shining through while still allowing water to drain from your sign. Light baffles are not considered standard, so you should always inquire about them if this is important to you.

MATERIAL SIZES

The aluminum and acrylic materials from which a sign is made typically come in standard size sheets. This means that if a channel letter exceeds the size of a sheet, you could end up with a seam in your can or letter face. Most skilled sign companies will position and fabricate seams in such a way that you won’t be able to see them, but if this sounds like something you don’t want, your sign company should be able to present you with a few options to avoid that outcome.

There is a lot more to know about channel letters, but we hope our simple guide has helped you gain a better understanding of this popular signage choice. If you have any questions about this information, or want to know how we can help you with your signage project, please call 631-446-1121 or submit a request via our contact page.